|

{tab=INTRODUCTION} The Rhino Pallet Nailing Machine™ is a robust and highly diverse pallet nailing system capable of building 600 pallets per day.

The flexibility of the pallet clamping system allows for easy change over accommodating pallet configurations from 3 to 4 stringer pallets design. The pallet clamping system squarely secures the boards and precisely positions them for the nailing process. To eliminate builder fatigue the Rhino Pallet Nailing Machine™ operates with push button controls allowing the pallet assembly to travel through the pneumatic nailing tools that fastens both the top & bottom deck boards’ simultaneously eliminating the need to turn over the pallet. The Rhino Pallet Nailing Machine™ as an option may come with and adjustable pallet stacker and optional gravity or powered out-feed conveyor allowing the pallet to be stacked to the required height making it the most valuable machine for any pallet production. The Rhino Pallet Nailing Machine™ is highly effective in doubling the production rate compared to manual pallet nailing. The Rhino Pallet Nailing Machine™ can hold 3000 nails per coil per nailing gun which means that approximately 150-200 pallets can be produced before any reloading is required. Please note that the customer needs to supply a proper air compressor needed to operate the pallet nailing machine. The air compressor is not included in the purchase price but can be added on as an additional option. A recommendation is provided which meets the pallet nailing machine requirements. {tab=VIDEO} BC Market Solutions™ has complementary videos of The Rhino Pallet Nailing Machine™ in full pallet production. Feel free to view our video library for any additional information regarding system set up and controls. [highlight_button_blue] Click here to view Video [/highlight_button_blue]

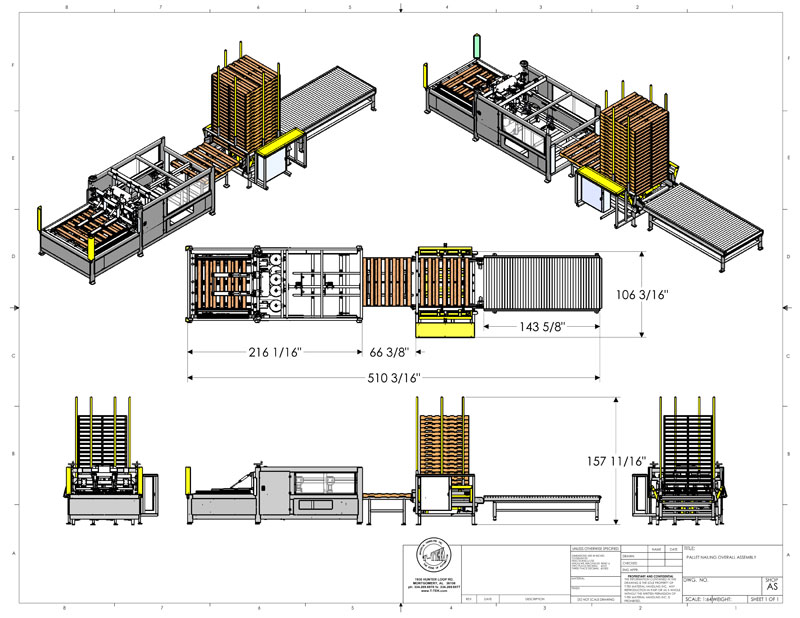

If you require a DVD and quotation please feel free to fill in your contact information and one will be mailed to you. {tab=OVERALL FEATURES} The Rhino Pallet Nailing Machine™ is a complete nailing system equipped with pallet making machine, quality inspection zone, pallet stacker and gravity out-feed conveyor. Below are just a few highlighted features that represents the overall quality of the to the pallet nailing machine.

{tab=REQUIREMENTS} When installing the Rhino Pallet Nailing Machine™ it is require that the customer have an area free and clear of any debris and enough space to operate the pallet making machine freely. The customer is responsible to bring in a dedicated air supply to the machine which has enough air volume to operate it without any interruptions. Further the customer will be responsible for hire a licensed electrician to terminate the power supply into the main panel. Below is a list of equipment & requirements needed to operation the machine.

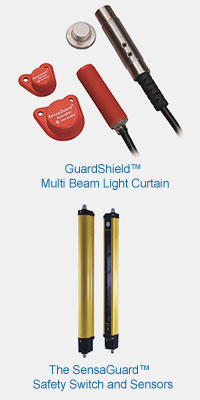

{tab=MECHANICAL DRAWING} {tab=SAFETY FEATURES} The Rhino Pallet Nailing Machine™ Safety Switches and Sensors are designed and built to global standards for high reliability, stability, and quality. Our safety sensors are integrated throughout the machine which gives us a full closed loop system to protect personnel working on or around the machine. If any reason that E-Stops or other sensor are deployed then the entire pallet nailing machine shuts down.

Our Perimeter Access Control System provides detection at the machine access points such as the pallet jig and access doors. The SensaGuard™ non-contact interlock inductive switches are mounted on all access doors to detect entry and the switches hold up well in our harsh industrial environment. To increase early entry detection our safety light curtain, mounted around the pallet jig loading zone is a photoelectric presences sensor that protects personnel from the machines motion which makes this device a valuable component where protection is needed. Collectively when these safety systems are in place, The Rhino Pallet Nailing Machine™ becomes a joint partner towards your integrated solution on exercising your corporate safety standards. {tab=BLOCK PALLET} The Rhino Pallet Nailing Machine™ is capable of building some of the Chemical Pallets (CP) and UK pallet designs. The most prominent international pallet styles are the open ended legged pallet design and perimeter base pallet such as a 1200mm x 1000mm block pallet. This block pallet design is acceptable across most distribution outlets. The pallet build requires that the customer pre build the block stringers or legs ahead of time. The open ended leg design will allow the machine to cycle and nail the pallet in a single pass. The perimeter base pallet will require you to flip the pallet over and then nail the (2) outside bottom board in place. The nail pattern across the deck boards will only be in a straight line. Optional Nail Plates can be installed into the jig allowing any nail stubble to be clinched during the nailing process. If the stagger nail pattern is required then the pallet machine will need to be modified and additional cost will apply. Please inquire about our additional machine to pre build your block stringers (leg machine). OPEN ENDED LEGGED BLOCK PALLET

|

|---|

|

Type:

|

Pallet

|

|---|---|

|

Minimum Pallet Size:

|

36″ x 36″ or (914mm) x (914mm)

|

|

Maximum Pallet Size:

|

60″ x 60″ or (1524mm) x (1524mm)

|

|

Maximum Stringers:

|

3 or 4 stringer boards per pallet

|

|

Maximum Boards:

|

Variable, space gap can be adjusted

|

|

Deck-board Length:

|

36″ up to 60″

|

|

Deck-board Thickness:

|

½” up to 1″

|

|

Deck-board width

|

3-½” and up

|

|

Stringer Board Length:

|

36″ to 60″ long

|

|

Stringer Height:

|

3 ½”

|

|

Stringer Width:

|

1 ½” to 3 ½”

|

|

Pallet Height:

|

4 ½” up to 5 ½”

|